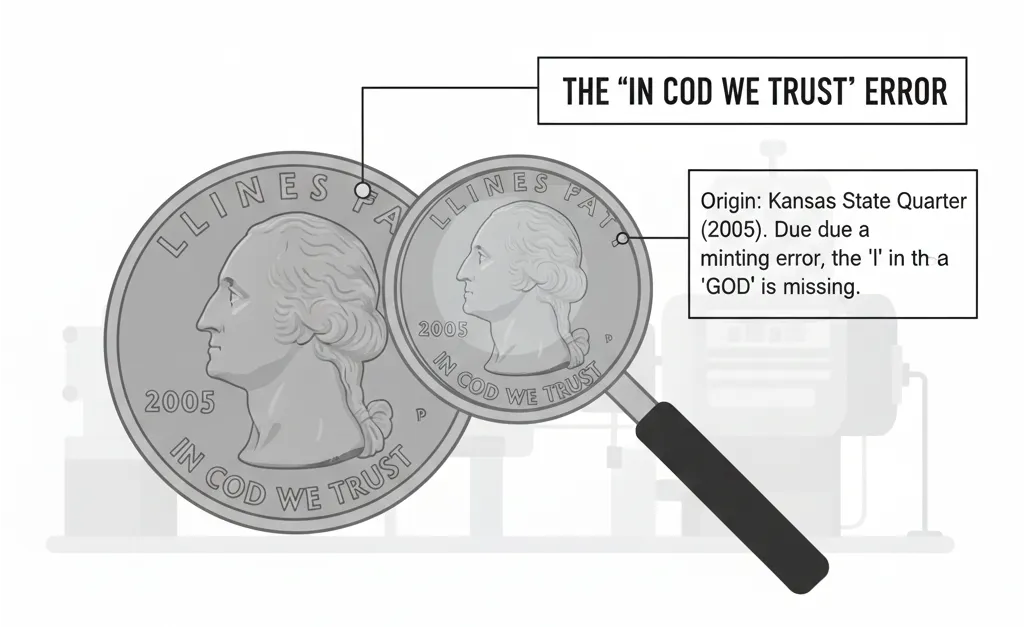

Starting a special program in 1999, the United States Mint released a coin dedicated to the state of Kansas in 2005 as part of the “50 State Quarters” series.

This specific issue becoming a subject of intense attention among coin collectors due to the appearance of a specific defect on the obverse side, the error is widely known as In Cod We Trust Quarter.

Understanding the nature of this phenomenon, we must first consider the standard technical characteristics of the production.

Located exclusively on the obverse of the coin in the area of the national motto, the “In Cod We Trust” error appears to the left of Washington’s portrait.

Mechanics of the Error: Struck Through Grease

Being a technical failure on the Kansas quarter, this error does not result from incorrect engraving or a defect in the design itself. Classified as “Struck Through Grease” (meaning minting through technical lubricant or dirt), this problem represents one of the most common production issues at modern mints.

The Role of Lubricants in the Press

Operating at extreme speeds, modern minting presses perform several hundred strikes per minute. Requiring a constant supply of thick technical grease to ensure the smooth operation of press units, feeding mechanisms, and the dies themselves, the machines consume large amounts of lubricant.

Mixing with microscopic metal dust from the blanks and fragments of scale during the work process, excess grease can accidentally fall onto the surface of the die.

The Process of Filling Die Cavities

Representing a negative image of the future design, the die has letters and small details appearing as deep holes or cavities. When a viscous mixture of grease and dust hits the die, it tends to accumulate exactly in these cavities under the influence of centrifugal force or high pressure.

In the case of the Kansas quarter, the lubricant mass filled the cavity corresponding to the letter “G” in the word “GOD,” preventing the metal from forming the correct shape.

Hydrodynamics of the Strike

Reaching pressures of tens of tons per square inch during the strike, the die hits the metal blank with enormous force. Being a practically incompressible substance, grease creates a physical barrier. If the cavity for the letter “G” is completely filled with this mass, the metal of the blank cannot enter this space.

Resulting in a flat surface on the spot where the letter should be, this process makes the letter disappear completely or partially depending on the amount of grease. Filling exactly the letter “G” on the Kansas quarter while leaving the neighboring letters “I”, “N”, “C”, “O”, and “D” untouched, the grease turned the phrase “IN GOD WE TRUST” into “IN COD WE TRUST.”

Stages of Die Degradation During Grease Accumulation

Not being a binary state (meaning it is not just “present” or “absent”), the “In Cod We Trust” error represents a spectrum of conditions depending on the degree of cavity filling.

Initial Stage (Faint G)

Becoming less deep and less clear during the first stages of grease accumulation, the letter “G” starts to lose its sharp edges. Merging with the field of the coin in its central part, the letter looks weak. Such examples have minimal numismatic value for professionals.

Intermediate Stage (Partial G)

Disappearing completely in its lower part, the letter “G” remains visible only as a thin line in the upper section. Starting to be identified as an “In Cod” variety at this moment, the coin attracts the interest of amateur collectors.

Full Stage (Full In Cod)

Being completely absent, the letter “G” leaves the surface of the coin absolutely smooth at this spot. Staying at the same level as the surrounding field of the coin, this area shows no trace of the strike. Classified as a full error, these specimens have the greatest market interest.

Technical Factors Explaining the Kansas Case

Occurring on many different coins, errors of the “Struck Through Grease” type became particularly famous on the Kansas quarter. This situation resulted from a combination of several specific technical factors.

Depth of the Motto Relief

Using a relatively small and shallow font for the “In God We Trust” motto in the 2005 quarter design, the Mint created conditions for easy filling.

Being small, these cavities are filled by viscous substances more easily and are cleaned less effectively during the natural vibration of the press.

Location of the Letter “G”

Situated in an area where the pressure of the die is distributed in a specific way during the formation of Washington’s portrait, the letter “G” became a trap for grease. Neighboring elements of the relief helped to hold the lubricant exactly in this point, preventing it from moving away.

Quality Control at the Mints

Producing huge numbers of coins in 2005 (Philadelphia making 263,400,000 Kansas quarters and Denver making 300,000,000), the US Mint faced difficulties with visual control. Working for a long time before technical cleaning or replacement, dies with grease continued to produce coins with the “In Cod” error.

Identification and Expert Evaluation

Requiring methods of technical surface analysis for accurate identification, the “In Cod We Trust” error must be checked carefully.

Toolset

Recommending the use of a microscope with 20x to 40x magnification or a coin evaluator for analysis, experts look for small details. Using oblique lighting is important for revealing residual traces of the relief.

Difference from Mechanical Wear

Distinguishing the production error from post-minting modification (meaning the mechanical removal of the letter) is necessary for every buyer.

- Surface: Showing the same texture (Luster) as the rest of the coin field, the surface at the site of the missing letter proves it is a grease error.

- Tool Marks: Creating micro-scratches and breaking the concentric lines of the minting shine, mechanical removal (sanding) is easy to detect under a microscope.

- Weight: Having no effect on the weight of the coin, the grease filling error differs from deep sanding, which might reduce the weight slightly.

Market Value and Numismatic Significance

Depending directly on the degree of the “G” disappearance and the general grade of the coin, the market price varies significantly.

Grading (Scale 1-70)

- Circulated Condition: Found in daily change, coins with a completely missing “G” are usually valued between 5 and 20 dollars.

- Uncirculated Condition (MS-60 – MS-64): Costing from 30 to 75 dollars, these coins stay popular among middle-level collectors.

- Gem Uncirculated Condition (MS-65 and higher): Reaching prices of 100–250 dollars, specimens certified by companies like PCGS or NGC are very rare.

Becoming a cultural phenomenon due to the funny sound (the word “Cod” meaning a type of fish), the “In Cod We Trust” error created a phrase “In fish we trust.” Providing demand not only from professional numismatists but also from the general public, this humor supports the liquidity of the coin.

Other Die Defects on the Kansas Quarter

Recorded on the 2005 issue, other technical deviations exist alongside the main grease error can also be determined with the best coin app.

“Spitting Bison”

Showing a die crack passing from the bison’s mouth downwards on the reverse of the coin, this defect creates a thin line effect.

Often accompanying dies with an “In Cod” obverse, this error indicates the general degradation of the equipment during that period of minting.

“Humpback Bison”

Being a metal bump in the area of the bison’s hump caused by die chipping (Die Chip), this is another indicator of heavy equipment use.

Indicating that the dies for the Kansas quarter were operated until the limit of their life, these marks help to identify specific production periods.

Die Cleaning Procedure

Performing a technical stop of the line when a press operator finds “Struck Through” errors, the Mint workers follow a strict protocol.

- Die Removal: Taking the die out of the holder, workers prepare it for cleaning.

- Solvent Washing: Using technical alcohols or specialized solvents for removing the viscous mass, they clean every cavity.

- Polishing: Subjecting the surface of the die to light polishing for restoring the micro-relief, workers ensure the quality of future coins.

- Test Minting: Checking the first few strikes for any remaining grease, the team restarts the production.

Representing limited series within a giant production run, “In Cod We Trust” coins appeared only during short intervals between the die getting dirty and being cleaned.

Statistics and Distribution Between Mints

Occurring on coins from both Philadelphia (P) and Denver (D) according to numismatic records, the error is not unique to one factory. However, specimens from Philadelphia appear 2.5 times more often than those from Denver.

Batch Analysis

Using a lubricant with higher viscosity or breaking the schedule of technical maintenance for die pairs in the third quarter of 2005, the Philadelphia Mint produced more errors.

Having better quality control, the Denver Mint made the “In Cod We Trust” versions rarer and more valuable for collectors today.

Influence of the Error on Die Durability

Protecting the metal of the die from direct contact with the blank in the place of the blockage, the grease filling technically prevents some wear. However, it also creates an uneven distribution of the load.

- Developing zones of high stress around the filled letter “G,” the die often gets micro-cracks (Die Stress Lines).

- Acting as an abrasive when containing metal dust, the grease under high pressure causes fast wear of the surrounding field (creating an “Orange Peel” texture).

Helping experts to confirm the authenticity of the “In Cod We Trust” error, these accompanying signs are practically impossible to copy during illegal modification of the coin.